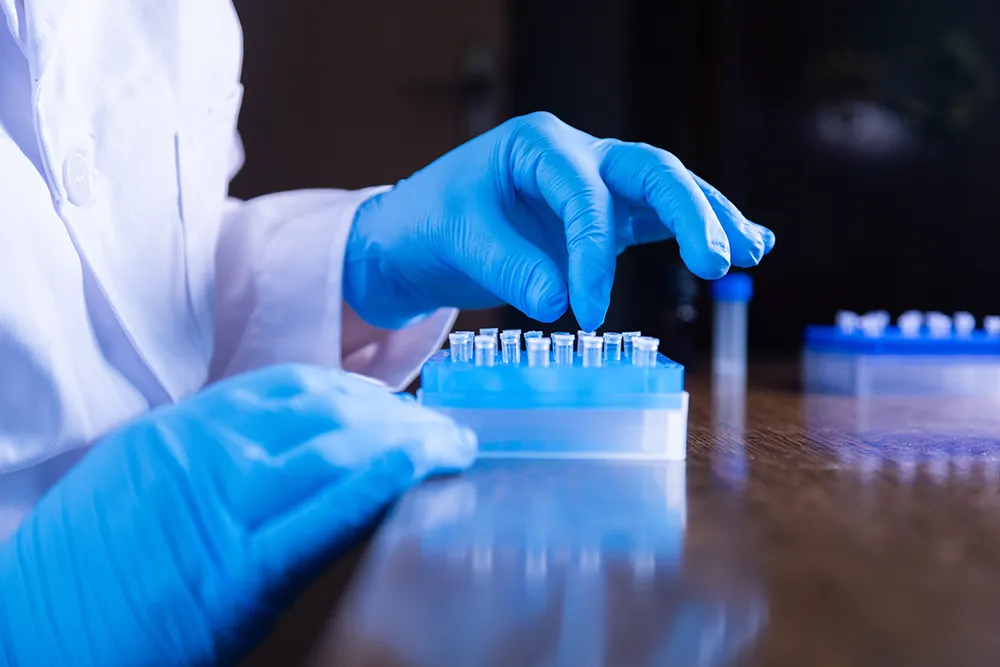

GxP comprises a collection of quality and safety guidelines and regulations designed to ensure that products and processes adhere to rigorous standards to ensure patient safety and well-being. GxP continues throughout the product development lifecycle, from the preclinical phase, manufacturing, distribution, and clinical development through post-product approval.

GxP Strategy Consulting

Our Allucent A-Team is highly proficient in providing strategic guidance and advising on complex GxP issues as they arise. We also offer support in investigating and resolving compliance issues in all phases of research and development. With deep expertise in clinical trials, our A-team has decades of experience in legislation and compliance as well as pharmacovigilance; several have served as inspectors with regulatory agencies.

Allucent’s GxP Strategic Expertise

- Good Clinical Practice (GCP)

- Good Laboratory Practice (GLP)

- Good Distribution Practice (GDP)

- Good Manufacturing Practice (GMP)

- Clinical Safety and Pharmacovigilance

GxP Consulting Services

- Provide inspection readiness to ensure compliance with regulatory and GxP requirements

- Conduct medical device and thorough GXP audits, including pre-approval inspections to mitigate risks and maintain regulatory compliance

- Support clinical trial conduct and compliance through site audits, TMF audits, and vendor audits

- Utilize a risk-based and risk-proportionate forward-thinking approach to ensure quality processes are always embedded throughout clinical trial programs

Inspection Readiness

As a best practice, inspection readiness is a continuous, ongoing program dedicated to consistently maintaining high-quality processes and deliverables. From the standpoint of a regulatory authority, organizations must be inspection-ready at any time. During the inspection, the goal is to verify that processes and systems are compliant with regulatory obligations supporting the safety and well-being of trial participants and that the data is reliable. A risk-based, forward-thinking approach assures that quality processes are always embedded throughout clinical trial programs for full compliance and inspection preparedness.

Our GxP Scope of Services

- GxP compliance assessment

- TMF audits

- Clinical investigator site audits and vendor/service provider audits [routine or “for cause”]

- Database audits

- Regulatory agency inspection readiness

- Support for regulatory agency inspections [“Back room”]

- Mock inspections

- GxP or GCP training

- FDA Form 483 and warning letter response assistance

- Vendor qualification

- Create SOPs and support on:

- Authoring

- Review

- Gap analysis

- QMS development

- GLP Audits

- Data quality audits

- GMP Audits

- Quality Management System (QMS) development

- Establishment of quality agreements and manuals

- QA review of master/executed batch records, specifications, test methods, validation and stability, protocols and reports

- PAI readiness assessment and training